Dutch semiconductor equipment manufacturer ASML Holding NV has delivered a stunning financial performance that exceeded market expectations, with quarterly revenue surging past projections and new orders reaching unprecedented levels. The Veldhoven-based company, which maintains a virtual monopoly on the production of extreme ultraviolet (EUV) lithography systems essential for manufacturing the world's most advanced chips, reported figures that sent shockwaves through the global semiconductor industry.

The company's latest earnings report revealed revenue of €6.7 billion for the quarter, comfortably surpassing analyst estimates of €6.4 billion. More significantly, ASML recorded net new orders totaling €9.19 billion, nearly triple the figure from the previous quarter and setting a new company record. This remarkable order intake, predominantly driven by demand for the company's cutting-edge EUV systems and the newer High-NA EUV technology, signals robust future growth and underscores the semiconductor industry's continued investment in advanced manufacturing capabilities despite broader economic uncertainties.

Chief Executive Officer Peter Wennink attributed the exceptional performance to multiple converging factors. "What we're witnessing is essentially a perfect storm of favorable market conditions," Wennink explained during the earnings call. "The ongoing digital transformation across all sectors, combined with the global chip shortage that has persisted longer than many anticipated, has created unprecedented demand for our technology. Additionally, government initiatives worldwide to bolster domestic semiconductor production have accelerated investment decisions that might otherwise have been delayed."

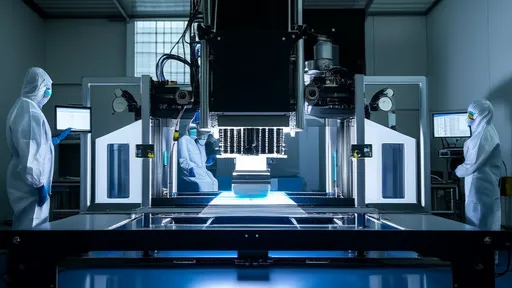

The company's order book now extends well into 2025, with lead times for its most advanced systems stretching beyond 24 months. This backlog reflects the immense complexity of ASML's technology and the limited number of systems the company can produce annually. Each EUV machine contains approximately 100,000 components and requires 40 freight containers to transport, with assembly taking up to six months. The sheer scale of these systems, which can cost upwards of $200 million each, means that production capacity remains a significant constraint despite ASML's continuous efforts to ramp up output.

Industry analysts have been particularly impressed by the diversity of customers driving this demand surge. While traditional semiconductor powerhouses like Taiwan Semiconductor Manufacturing Company (TSMC), Samsung Electronics, and Intel continue to account for the bulk of orders, ASML has seen growing interest from newer market entrants and companies in regions with emerging semiconductor ambitions. The United States' CHIPS Act, Europe's Chips Act, and similar initiatives in Japan and India have created a new wave of potential customers looking to establish or expand domestic chip manufacturing capabilities.

The company's technological leadership remains unchallenged, with its EUV systems representing the only viable solution for manufacturing chips with features smaller than 7 nanometers. These advanced processors power everything from the latest smartphones and computers to artificial intelligence systems and military applications. ASML's upcoming High-NA EUV technology, which offers even higher resolution for producing chips with features below 2 nanometers, has generated particular excitement, with multiple customers already placing orders for these next-generation systems scheduled for delivery in 2024.

Despite the impressive results, ASML faces significant challenges in maintaining its trajectory. The company continues to navigate complex geopolitical tensions, particularly concerning exports to China. Recent restrictions imposed by the Dutch government, following pressure from the United States, have limited ASML's ability to ship its most advanced systems to Chinese customers. While this represents a relatively small portion of the company's overall business in the short term, the long-term implications remain uncertain as China accelerates its efforts to develop domestic alternatives to ASML's technology.

Supply chain constraints also present ongoing difficulties. ASML relies on a network of over 5,000 suppliers worldwide, many of whom are struggling with their own capacity limitations and material shortages. The company has been working closely with key suppliers to address bottlenecks and has even begun acquiring strategic suppliers to secure critical components. These efforts have yielded some success, but executives acknowledge that supply chain pressures will likely persist through 2024.

The financial markets have responded enthusiastically to ASML's performance, with the company's share price climbing approximately 8% following the earnings announcement. This boost comes after a challenging period for semiconductor stocks, which have been battered by concerns about potential oversupply in certain chip categories and broader economic headwinds. ASML's results have provided a much-needed vote of confidence in the sector's underlying strength and long-term growth prospects.

Looking ahead, ASML has maintained its previous guidance for 2024, projecting revenue growth of approximately 20% compared to 2023. However, many analysts believe this forecast may prove conservative given the current order momentum. The company plans to increase its production capacity for EUV systems to 90 units annually by 2026, up from approximately 60 units in 2023, and is simultaneously ramping up production of its Deep Ultraviolet (DUV) systems, which remain crucial for manufacturing less advanced but still widely used chips.

ASML's success story reflects broader trends in the global technology landscape. The increasing importance of semiconductors across all aspects of modern life, from consumer electronics to national security, has created a sustained investment cycle that shows no signs of abating. As countries and companies recognize the strategic importance of controlling their chip supply chains, demand for the advanced manufacturing equipment that ASML provides continues to intensify.

The company's research and development efforts remain as ambitious as ever, with annual R&D spending now exceeding €3 billion. This substantial investment ensures that ASML maintains its technological edge while developing the next generation of lithography systems that will be needed to continue the march of Moore's Law. Industry observers widely agree that without ASML's continued innovation, the semiconductor industry would struggle to maintain its historical pace of advancement.

ASML's position at the heart of the global technology ecosystem gives it unique insights into industry trends. Company executives note that they're seeing particularly strong demand driven by multiple technology transitions happening simultaneously. The adoption of artificial intelligence and machine learning across various applications requires increasingly powerful processors, while the rollout of 5G networks demands more sophisticated chips for both infrastructure and devices. The automotive industry's rapid shift toward electrification and autonomous driving represents another significant growth driver, with modern vehicles incorporating more semiconductors than ever before.

The company's remarkable order intake has prompted some concerns about potential overcapacity in the semiconductor industry down the line. However, ASML management remains confident that current investments are justified by fundamental demand growth rather than speculative excess. They point to the increasing chip intensity of the global economy and the lengthy lead times required to build new semiconductor manufacturing facilities as factors that will prevent the kind of dramatic boom-and-bust cycles that have characterized the industry in previous decades.

ASML's performance stands in stark contrast to many other technology companies that have faced challenges in recent quarters. While consumer-focused tech firms have struggled with slowing demand and inventory corrections, ASML has benefited from its position at the beginning of the semiconductor value chain. The company's systems are essential for building the manufacturing capacity that will produce the chips needed for future technology applications, insulating it from short-term fluctuations in end-market demand.

As the global economy navigates uncertain territory, ASML's results provide a compelling case study in strategic positioning and technological indispensability. The company's ability to exceed expectations during a period of broader economic anxiety underscores the critical nature of its products and the limited number of viable alternatives available to semiconductor manufacturers worldwide. With its order book filled for years to come and its technological leadership secure, ASML appears well-positioned to maintain its extraordinary performance trajectory for the foreseeable future.

By /Nov 5, 2025

By /Nov 5, 2025

By /Nov 5, 2025

By /Nov 5, 2025

By /Nov 5, 2025

By /Nov 5, 2025

By /Nov 5, 2025

By /Nov 5, 2025

By /Nov 5, 2025

By /Nov 5, 2025

By /Nov 5, 2025

By /Nov 5, 2025

By /Nov 5, 2025

By /Nov 5, 2025

By /Nov 5, 2025

By /Nov 5, 2025

By /Nov 5, 2025

By /Nov 5, 2025

By /Nov 5, 2025

By /Nov 5, 2025