Chile's copper mining industry is undergoing a revolutionary transformation as it embraces digitalization with the launch of comprehensive 5G-enabled smart mining projects across its vast mineral-rich territories. The nation, long recognized as the world's leading copper producer, is now positioning itself at the forefront of mining technology innovation through strategic partnerships between state agencies, mining corporations, and telecommunications providers.

The ambitious initiative represents a significant departure from traditional mining operations that have characterized Chile's extractive industry for decades. Mining companies including Codelco, BHP, Anglo American, and Antofagasta Minerals have committed substantial investments to integrate 5G connectivity with advanced automation systems, artificial intelligence, and Internet of Things (IoT) technologies throughout their operations. This technological leap forward aims to address longstanding challenges in safety, productivity, and environmental sustainability while maintaining Chile's competitive edge in global copper markets.

The implementation of 5G networks in remote mining locations marks a technological milestone for the industry. Unlike previous generations of wireless technology, 5G offers the low latency, high bandwidth, and massive device connectivity required to support real-time monitoring and control of mining operations. This enables seamless communication between autonomous vehicles, drilling equipment, and centralized control centers, creating an integrated ecosystem where data flows uninterrupted across the mining value chain.

At the heart of this transformation lies the development of underground 5G networks that maintain reliable connectivity hundreds of meters below the surface. These specialized networks support autonomous loading and hauling systems that operate with precision in challenging underground environments. The technology allows for continuous operation without human intervention in hazardous areas, significantly reducing exposure to dangerous working conditions while optimizing material movement through sophisticated algorithms that calculate the most efficient routes and loading patterns.

Surface mining operations are experiencing equally dramatic changes through the deployment of 5G-connected autonomous haul trucks that navigate massive open-pit mines with centimeter-level accuracy. These intelligent vehicles communicate with each other and with traffic management systems to coordinate movements, avoid collisions, and optimize fuel consumption. The elimination of human operators from these vehicles not only enhances safety but also enables operations to continue uninterrupted throughout shifts, increasing overall equipment utilization rates.

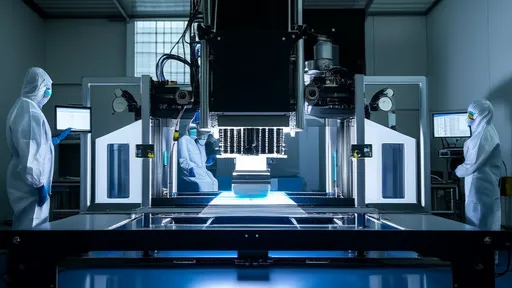

Remote operation centers represent another critical component of Chile's mining digitalization strategy. Located hundreds of kilometers from actual mine sites in urban centers like Santiago, these high-tech facilities enable specialists to monitor and control mining operations in real-time through immersive interfaces and haptic feedback systems. The ultra-low latency of 5G networks ensures that operators experience virtually instantaneous response times when controlling equipment remotely, making the physical separation between operator and machinery practically irrelevant from a functional perspective.

The environmental implications of this digital transformation extend beyond operational efficiency. Advanced sensor networks powered by 5G connectivity monitor air quality, water usage, and energy consumption throughout mining facilities, enabling precise management of environmental impacts. These systems can detect anomalies in real-time, triggering automated responses to mitigate potential environmental incidents before they escalate. The data collected also supports compliance reporting and provides transparency to regulators and local communities regarding mining operations' environmental performance.

Predictive maintenance represents one of the most economically significant applications of 5G technology in the mining context. By continuously monitoring equipment condition through vibration analysis, thermal imaging, and acoustic sensors, mining companies can identify potential failures before they occur. This proactive approach to maintenance reduces unplanned downtime, extends equipment lifespan, and optimizes spare parts inventory. The high-speed data transmission capabilities of 5G networks ensure that the vast amounts of sensor data required for these predictive models can be processed and analyzed in near real-time.

Workforce development has emerged as a critical consideration in Chile's mining digitalization journey. As operations become increasingly automated, the skill requirements for mining personnel are shifting from manual labor to technical expertise in data analysis, robotics, and network management. Mining companies have established comprehensive training programs in partnership with technical institutes and universities to prepare the next generation of mining professionals. These initiatives aim to ensure that Chilean workers remain competitive in an increasingly technology-driven industry while providing attractive career pathways beyond traditional mining roles.

The economic implications of this technological transformation extend beyond individual mining operations to impact Chile's position in global copper markets. By reducing production costs through improved efficiency and automation, Chilean mines can maintain profitability even during periods of price volatility. The increased reliability of automated operations also enhances Chile's reputation as a consistent and dependable supplier in global supply chains, a particularly valuable attribute as the world transitions toward electrification and renewable energy systems that depend heavily on copper.

International technology providers have established significant presence in Chile to support this digital transformation. Companies specializing in industrial automation, telecommunications infrastructure, and software development have formed dedicated mining divisions to cater to the specific requirements of Chilean operations. This influx of technological expertise has created a vibrant ecosystem of innovation around the mining sector, with research and development activities focused on adapting cutting-edge technologies to the unique challenges of mineral extraction.

The regulatory framework governing mining operations in Chile has evolved to accommodate these technological advancements. Government agencies have worked collaboratively with industry stakeholders to develop standards and protocols for autonomous mining systems, data security, and spectrum allocation for industrial 5G networks. This proactive regulatory approach has been instrumental in creating an environment conducive to technological experimentation and implementation while maintaining appropriate oversight of safety and environmental considerations.

Looking forward, the successful implementation of 5G-enabled smart mining in Chile serves as a blueprint for mineral extraction industries worldwide. The lessons learned from deploying these technologies in challenging environments—from the extreme altitudes of the Andes to the deep underground mines—provide valuable insights for other mining regions contemplating similar digital transformations. Chilean mining companies have begun exporting their technological expertise through consulting services and technology partnerships with mining operations in Peru, Canada, and Australia.

The digitalization of Chile's copper mining industry represents more than just technological upgrading—it signifies a fundamental reimagining of how mineral resources can be extracted safely, efficiently, and sustainably. As these 5G-enabled smart mining projects mature and expand, they establish new benchmarks for what is possible in extractive industries while reinforcing Chile's leadership in global copper production. The convergence of connectivity, automation, and data analytics in mining operations creates a foundation for continuous innovation that will likely shape the industry for decades to come.

By /Nov 5, 2025

By /Nov 5, 2025

By /Nov 5, 2025

By /Nov 5, 2025

By /Nov 5, 2025

By /Nov 5, 2025

By /Nov 5, 2025

By /Nov 5, 2025

By /Nov 5, 2025

By /Nov 5, 2025

By /Nov 5, 2025

By /Nov 5, 2025

By /Nov 5, 2025

By /Nov 5, 2025

By /Nov 5, 2025

By /Nov 5, 2025

By /Nov 5, 2025

By /Nov 5, 2025

By /Nov 5, 2025

By /Nov 5, 2025